(303) 420-8242 | 7333 W. Jefferson Ave., Suite 235, Lakewood, CO 80235 USA

(303) 420-8242 | 7333 W. Jefferson Ave., Suite 235, Lakewood, CO 80235 USA

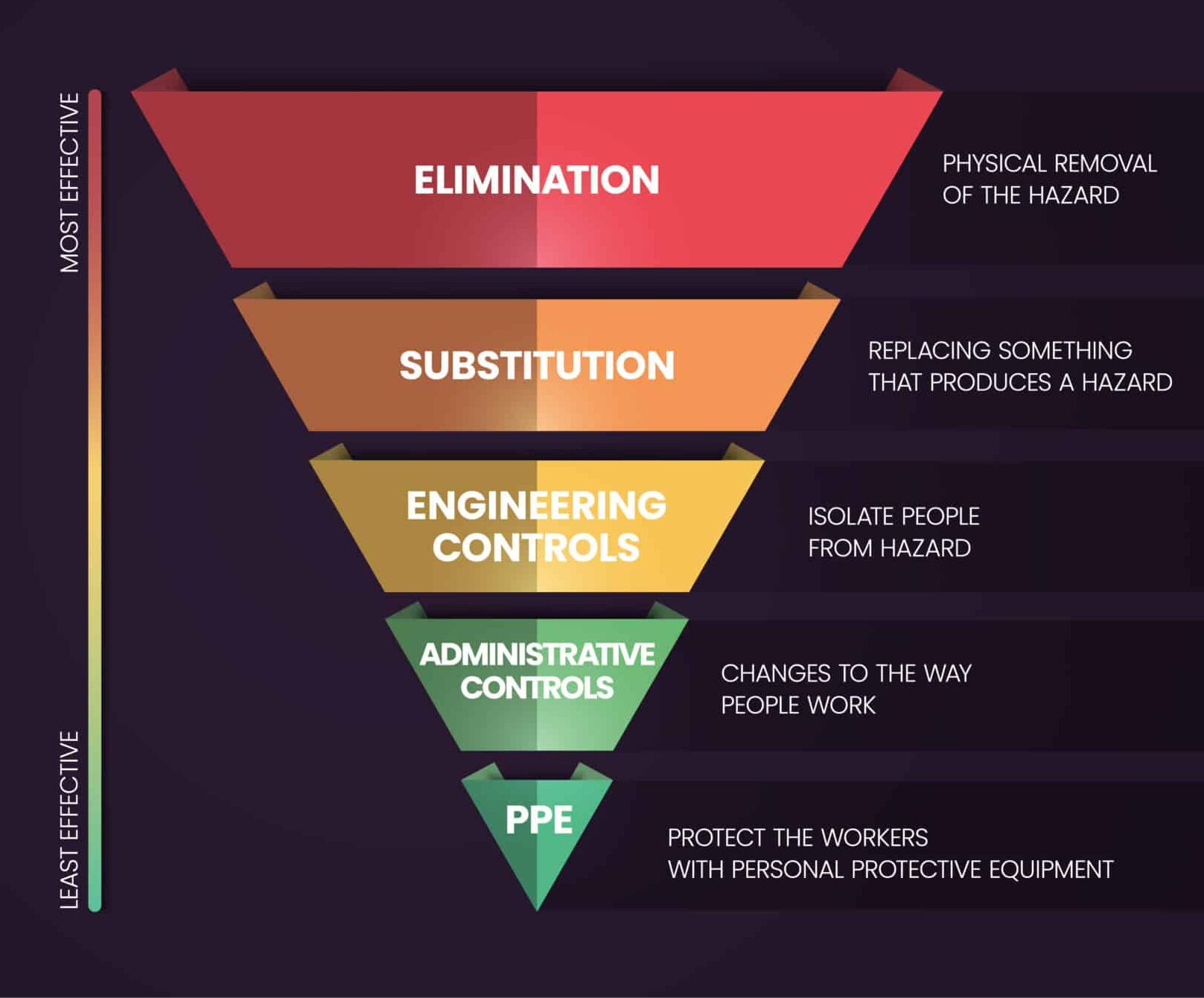

C&IH helps organizations identify and implement different approaches for protecting workers from hazardous exposures, aligning with the hierarchy of controls established by NIOSH.

The ideal approach for managing a workplace health exposure is elimination or substitution of the hazardous agent. When this type of process modification cannot be achieved, the next best approach is to implement an engineering control. If an engineering control is not possible, then administrative controls and personal protective equipment may be necessary. C&IH helps organizations identify and implement the most practical and effective approach for protecting workers.

Engineering controls are designed to improve workplace safety by minimizing or eliminating the need for administrative controls or personal protective equipment, thereby reducing the potential for contaminant exposures. Reducing or removing health and safety hazards can be realized through various means including modification of equipment or a working area, adding barriers or other protective elements, and improved ventilation.

Our engineering group specializes in the assessment and design of local exhaust ventilation (LEV) and general exhaust ventilation systems to control airborne contaminant exposures generated by a wide variety of industry-specific materials and processes including those associated with chemical, gas, dust, fume, vapor, mist, aerosol, particulate, fiber, and biological materials. Consulting activities performed by our engineering group that focus on ventilation systems include:

C&IH’s ventilation engineering services are designed to reduce occupational health risk by controlling workplace exposures when other options for removing a hazardous agent are not feasible.

Eval of a complex ventilation system at an insulation manufacturing facility to determine the adequacy of the system’s ability to capture airborne particulates, and the design of new dust collector LEV and general exhaust system components.

Assessment of a ventilation, dust collection, and exhaust system related to the adequacy of the system’s formaldehyde and fiber extraction capabilities at a manufacturing facility.

Assessment of carbon dioxide (CO2) concentrations and subsequent recommendations for appropriate ventilation controls at a meat packing plant.

Assessment of a ventilation system and the development of a conceptual design for an LEV system to address mercury vapor at a precious metals refinery.

Design and commissioning of a control room air pressurization and filtration system to prevent infiltration of diesel particulate matter and asbestos at an underground mining operation.

C&IH utilizes computational fluid dynamics (CFD) modeling, as well as other modeling tools, in various capacities to support ventilation engineering projects.

Examples include using CFD to evaluate the effectiveness of a proposed new LEV or general exhaust system before it is built, to determine the proper optimization of an existing system in response to a new work process or changing worksite conditions, or for troubleshooting ventilation system performance.